Using the information below compute the raw materials inventory turnover – Using the information below to compute the raw materials inventory turnover is a crucial aspect of inventory management. It provides valuable insights into the efficiency of a company’s raw materials usage and can significantly impact overall profitability.

This comprehensive guide will delve into the concept of raw materials inventory turnover, its significance, and the factors that influence it. We will also explore the formula for calculating this ratio and provide best practices for improving it.

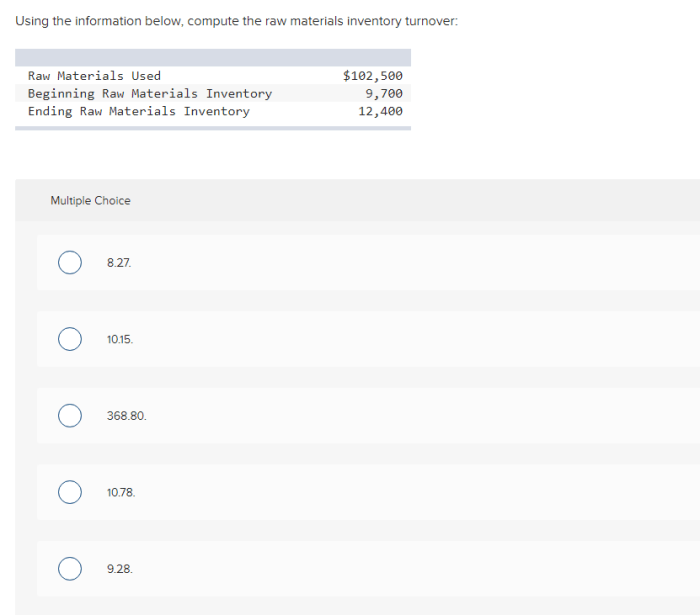

Understanding Raw Materials Inventory Turnover

Raw materials inventory turnover measures how efficiently a company manages its raw materials inventory. It reflects the number of times raw materials are converted into finished goods and sold during a specific period.

Tracking raw materials inventory turnover is significant because it:

- Identifies potential inefficiencies in inventory management

- Helps optimize inventory levels, reducing waste and storage costs

- Improves cash flow by ensuring that raw materials are used effectively

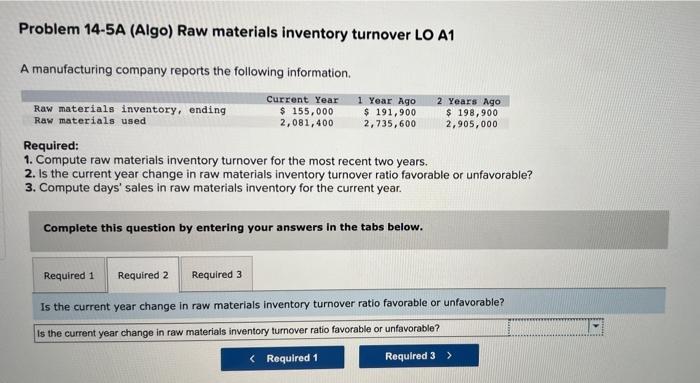

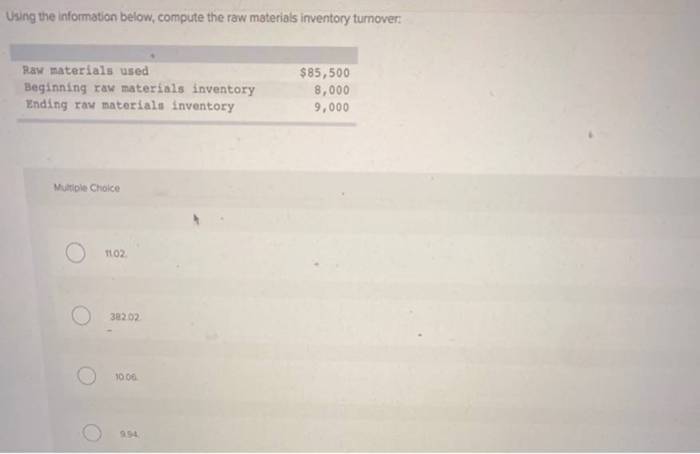

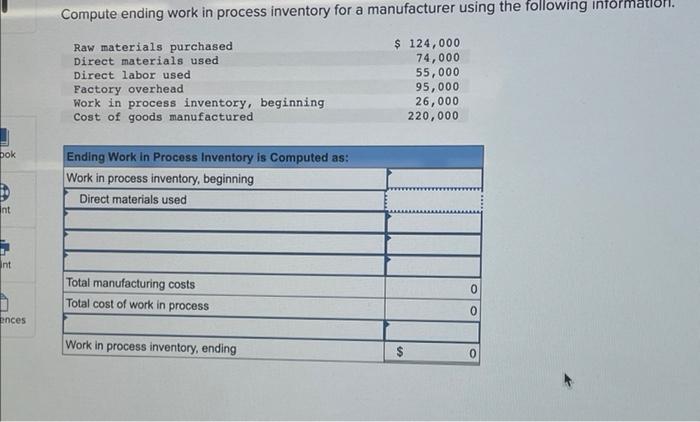

Calculating Raw Materials Inventory Turnover

The formula for calculating raw materials inventory turnover is:

Cost of Goods Sold / Average Raw Materials Inventory

Components of the Formula:

- Cost of Goods Sold (COGS):Represents the total cost of raw materials used in producing finished goods.

- Average Raw Materials Inventory:Calculated as the average of beginning and ending raw materials inventory over the period.

Factors Affecting Raw Materials Inventory Turnover

Several factors can influence raw materials inventory turnover, including:

- Production Volume:Higher production volume leads to increased raw materials usage, potentially improving turnover.

- Inventory Management Practices:Effective inventory management techniques, such as just-in-time (JIT) inventory, can reduce inventory levels and improve turnover.

- Supplier Lead Time:Longer lead times require higher inventory levels, potentially reducing turnover.

- Product Variety:A wide product range can result in larger and more complex inventory, potentially impacting turnover.

- Demand Fluctuations:Unpredictable demand can lead to inventory overstocking or understocking, affecting turnover.

Interpreting Raw Materials Inventory Turnover Results

High raw materials inventory turnover indicates efficient inventory management, while low turnover may suggest inefficiencies or excess inventory.

- High Turnover:Indicates that raw materials are being used effectively and converted into finished goods quickly, resulting in reduced inventory costs and improved cash flow.

- Low Turnover:Suggests potential inefficiencies in inventory management, such as overstocking or slow-moving inventory, which can lead to increased storage costs and potential obsolescence.

Improving Raw Materials Inventory Turnover

To improve raw materials inventory turnover, companies can:

- Implement JIT Inventory:This technique minimizes inventory levels by receiving raw materials just before they are needed for production.

- Optimize Supplier Relationships:Establish reliable supplier relationships to ensure timely delivery and reduce lead times.

- Use Inventory Management Software:Leverage technology to automate inventory tracking, monitor stock levels, and identify potential inefficiencies.

- Conduct Regular Inventory Audits:Regularly review inventory levels to identify obsolete or excess inventory and take corrective actions.

- Analyze Demand Patterns:Forecast demand to anticipate future needs and adjust inventory levels accordingly.

Frequently Asked Questions: Using The Information Below Compute The Raw Materials Inventory Turnover

What is the formula for calculating raw materials inventory turnover?

Raw Materials Inventory Turnover = Cost of Goods Sold / Average Raw Materials Inventory

Why is it important to track raw materials inventory turnover?

Tracking raw materials inventory turnover helps businesses assess the efficiency of their inventory management practices, identify potential inefficiencies, and make informed decisions to improve profitability.

What are some factors that can affect raw materials inventory turnover?

Factors that can affect raw materials inventory turnover include production schedules, supplier lead times, storage capacity, and demand fluctuations.